Sensors Department

The Sensors Department has over a century of combined experience working in micro- and nano-fabrication clean rooms, with specific competencies in: Design, fabrication, and use of superconducting sensors and devices; High-density electronic interconnects and packaging; X-ray and particle detector system-integration, manufacture, assembly, and calibration; Semiconductor sensors and devices and micro-machining. The department works together with other TID departments and the Science Directorate in contributing to projects for cosmology, particle physics, neural science, medicine, accelerator diagnostics, and photon science. Furthermore, the Sensors Department develops TES spectrometers, soft x-ray cameras, and high-frame-rate detectors for LCLS-II first light and beyond.

Key Competencies

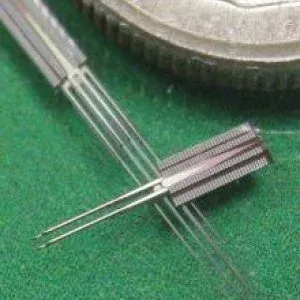

Interconnects and Packaging

Advanced interconnects and packaging design and fabrication. Fine pitch bump-bonding (down to 10 um pitch), gold stud bonding, assembly with diced chips, cro bumps, edge vias, flexible substrates, thin substrates, integrated micro-cooling conduits.

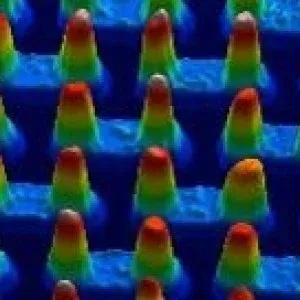

Microfabrication

Ability to access numerous micro and nano fabrication clean rooms and tools for fabrication and evaluation for: ion milling, metal deposition, organic film deposition, electron beam lithography, and focused ion beam patterning, etc.; as well as characterization: SEMs, TEMs, XRD, XPS, Auger, SIMS, SPMs, etc.

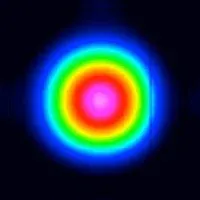

Micro Optics

Expertise in design, modeling, fabrication, and characterization of micro-electro-mechanical systems (MEMS) and micro-electro-optical-mechanical systems (MOEMS). Including micro-lenses, micro-mirrors, and optical imaging.

R&D on New Novel Devices

Novel instrumentation for biology and medicine, photon emission tomogrophy, and Super Conducting devices.

Sensor Design and Simulation

Design and simulation of advanced silicon sensors. TCAD simulation of fabrication process, transistors, sensor devices. Simulation of electro-static potentials, electric fields, signal collection.

Space-Based Detector Systems

Designed, built, qualified, assembled, tested most of electronics hardware, firmware, and software for FERMI Gamma-ray Large Area Telescope Instrument. 80 square meters of silicon sensors; Instrument assembled at SLAC; In orbit since 2008 with no failures, performs flawlessly. End-to-end on-board electronics: ASICs, printed-circuit boards, FPGA firmware, software code, 9 types of custom integrated circuits, flying 16,000 ASICs on board, complex data acquisition system. Chief Electronics/Electrical/Software Engineering, Systems engineering and integration. Complete qualification of electronics components (radiation, life-time, etc) and flight validation.

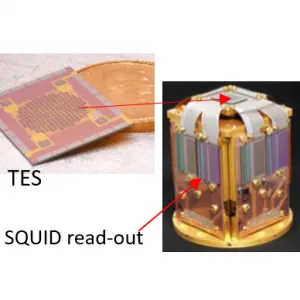

Superconducting Sensors, Devices, and Systems

R&D, design, and fabrication of Superconducting (mK) Quantum Interference Devices (SQUIDs), Transition-Edge Sensors (TES); Complete focal plane system design, fabrication and testing. Applications such as: Cosmology seeking signs of cosmic inflation, measuring polarization of cosmic microwave background; X-Ray Spectroscopy.

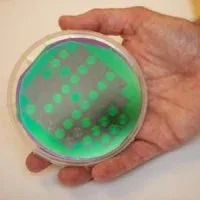

X-Ray Camera Systems

Complete turn-key design, fabrication, assembly and testing of X-Ray camera systems. Sensors, ASICs, electronics boards, firmware, software, mechanical/thermal assembly. Examples: Time-of-flight spectroscopy for electrons and ions, down to 30 ps resolution; Multiple types of Imaging cameras with low noise and high dynamic range at 50um and 100um pixel sizes, from 160,000 to 2,000,0000 pixels.